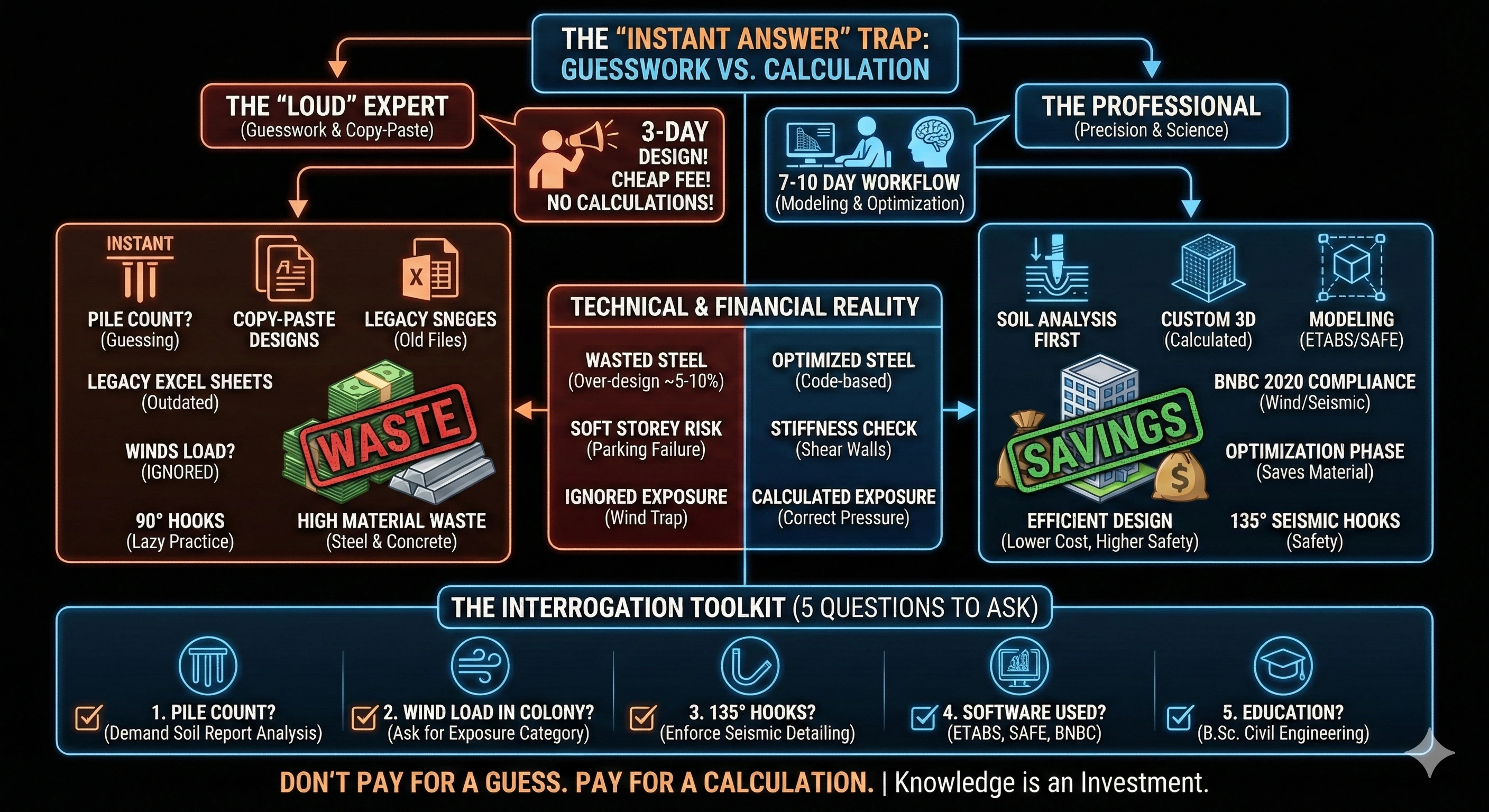

ATTENTION: The Danger of the "Loud" Expert

Imagine you walk into a doctor’s office. Before you even sit down, before you mention your symptoms, and before checking your blood pressure, the doctor hands you a prescription and says, "You need heart surgery. That will be 5 Lakh Taka."

Would you trust that doctor? Absolutely not. You would run. You know that a diagnosis requires data, tests, and analysis.

Yet, this is exactly what happens in the construction industry in Bangladesh every day. A landowner meets a potential structural engineer. They haven't shown the Soil Test Report. They haven't finalized the architectural floor plan. They haven't discussed the specific usage of the building.

But the "Expert" is loud. He is confident. After a basic conversation, he looks the client in the eye and says: "Brother, don't worry. This is a 6-story building. You will need 45 piles, 60 feet deep. The design will cost Tk. 15,000. I can give it to you in 5 days."

He sounds like he knows what he is doing. He sounds experienced. He is lying.

In engineering, Confidence without Calculation is Negligence. There is a massive difference between a New Engineer (who might charge less to build their portfolio but follows the rules) and an Ignorant Engineer (who charges less because they don't know the work).

A cheap fee from an ignorant person is often the most expensive thing a client will ever buy. They save Tk. 50,000 on fees today, but risk wasting Tk. 15,00,000 to Tk. 20,00,000 in unnecessary steel or, critically, compromising the building's safety.

This article explains the hidden mechanics of the "Copy-Paste" culture and provides the Interrogation Toolkit: specific technical questions that reveal if an engineer is a scientist or a gambler.

DESIRE: The High Cost of "Fast" Engineering

Clients often love the engineer who promises the design in 3 days. It feels efficient. But let’s look at what "3 Days" actually means.

The Timeline of Safety

A proper structural design workflow (even for a bright young engineer) takes time.

Day 1-2: Modeling the geometry in software (ETABS).

Day 3: Analyzing the Soil Report (calculating bearing capacity, settlement check).

Day 4: Applying Loads (Wind, Earthquake, Dead, Live) and running the analysis.

Day 5: The "What If" Phase. This is where the magic happens. The engineer checks: "What if I rotate this column? What if I reduce this beam size?" This is where they save you money by optimizing material.

Day 6-7: Drafting the drawings and detailing.

The 3-Day Rush Job: If an engineer promises the design in 3 days, they are skipping steps 2, 4, and 5.

- They aren't checking the soil properly.

- They aren't optimizing (which means they are wasting your steel).

- They are likely copy-pasting an old design.

The "New Firm" Advantages for clients: A new, young firm might charge you less (say, Tk. 60,000 instead of Tk. 1 Lakh) because they want your business. This is okay. Because a young engineer or firm with knowledge will likely take more time, not less. They will be meticulous to create process once and for all to be also prepared for the next project. They will check the code book three times. They will be obsessed with getting it right.

The Bottom Line:

- On a Budget? Hire the meticulous young engineer who takes 15 days.

- Want Zero Tension? Hire a renowned firm with a proven track record.

- The Rule: Never go to the "cheap and fast" option.

INTEREST: Anatomy of the "Copy-Paste" Fraud

To understand why "cheap" engineering is so expensive, one must understand the economics of the profession.

A proper structural design for a 6-story building requires significant time and computational power. It involves:

Modeling: Creating a 3D wireframe of the specific building in advanced software like ETABS.

Loading: Applying specific loads defined by the Bangladesh National Building Code (BNBC 2020)—wind loads, seismic (earthquake) loads, and dead/live loads.

Analysis: Running iterations to see how the building behaves under stress (drift, torsion, shear).

Design & Detailing: Calculating the exact rebar needed for every beam, column, and slab.

This process takes a skilled engineer 50 to 80 man-hours. At a fee of Tk. 15,000, that engineer would be earning less than a manual laborer per hour. It is mathematically impossible to do a genuine engineering design for that price.

So, how do they do it? They cheat.

1. The "Copy-Paste" Methodology

- The "Discount Engineer" does not design the building. They simply find a previous project they did years ago that looks "close enough."

- Does the land size look similar? Check.

Is it 6 stories? Check.

They open the old AutoCAD file, change the client name, change the location from "Uttara" to "Keraniganj," and hit print.

The Fatal Flaw: A building designed for the stiff, red clay soil of Gazipur behaves completely differently than a building on the sandy, liquefiable soil of Bashundhara.

- In Gazipur: The soil is hard; foundations can be shallow and isolated.

- In Bashundhara: The soil is soft; deep pile foundations are mandatory.

If a Gazipur design is copied for a Bashundhara plot, the building will sink. If the reverse happens, millions of Taka are buried in unnecessary concrete piles.

The "Legacy Excel" Trap: Another common trick is relying on outdated Excel sheets. These sheets, often created decades ago, act as "Magic Black Boxes." They do not account for modern BNBC 2020 restrictions, torsion, or irregular geometry. They simply spit out a generic, heavy reinforcement number. The engineer blindly trusts this sheet because they don't understand the underlying physics. The engineer using it may not know the formulation of that excel.

2. The "Rich Client" Tax (Guesswork Safety)

This is the most insidious part of the practice. Because the engineer isn't doing the math, they operate on Fear. They don't know the actual capacity of the columns because they never calculated it.

So, they look at the client. If the client arrives in a nice car, wears a suit, or emphasizes "I want a strong building," the engineer panics. They think, "This client is rich. If the building cracks, he will cause trouble. I better make it strong."

Without running a single calculation, they arbitrarily increase the column sizes.

- Does it need 16mm rods? "Let's put 20mm, just to be safe."

- Does the slab need to be 5 inches? "Let's make it 7 inches."

This is not engineering. This is gambling. They are using the client's money to buy their own peace of mind. They bury tons of extra steel in the concrete, not because the building needs it, but because they are too lazy to calculate that it doesn't need it.

FINANCIAL REALITY: The Mathematics of Waste

Some might think, "But isn't extra steel good? Isn't it safer?" Not necessarily. A heavier building attracts more earthquake force. But more importantly, let’s look at the financial damage.

Let’s analyze a typical G+5 Residential Building (6 stories total) on a 3-Katha plot.

Average Structural Cost (2026): Tk. 1,600 per sq. ft.

Total Structural Budget: Tk. 1.92 Crore (approx).

Scenario A: The "Guesswork" Design Because the engineer is guessing, they apply a "Safety Factor of Ignorance." They over-design the steel reinforcement by roughly 5% to 10% to cover their lack of calculation.

Wasted Steel: A typical 6-story building uses ~40 tons of rebar. A 5% waste is 2 tons. (This 2 tons costs roughly the same as a professional design fee).

Wasted Concrete: Thicker slabs and larger columns mean more cement, sand, and stone chips.

Estimated Concrete Waste: Tk. 6,00,000.

Total Waste: Tk. 13,84,000 (Minimum). The client saves Tk. 85,000 on design fees but loses Tk. 13.84 Lakhs in materials.

Scenario B: The Professional Precision Design A professional models the building in ETABS. They see that the beams on the 4th floor don't carry as much load as the 1st floor, so they reduce the steel there. They calculate the exact slab thickness needed for deflection, not an inch more.

Optimization: They save that waste while strictly adhering to BNBC codes.

The Result: The "Expensive" engineer effectively works for free and hands the client a massive saving.

CLIENT EDUCATION: 3 Technical Traps

Beyond the money, there are critical technical concepts that separate professionals from amateurs. Clients can use these three scenarios to test a potential engineer.

1. The "Wind Load" Trap (Exposure Definition)

This is a nuanced area where the "Noob" engineer fails completely.

The Scenario: The building is in a dense area like Mohammadpur or Mirpur, surrounded by other 6-story buildings.

The Unprofessional Answer: "Sir, your building is surrounded by others. Wind cannot hit it directly. We don't need to consider wind load. It will just increase the cost unnecessarily."

Why this is wrong: Ignoring wind load is illegal under BNBC 2020.

The Professional Answer: "Wind load is mandatory, but we calculate it smartly. Since you are surrounded by structures, your building falls under Exposure Category A or B (Urban/Suburban). This allows us to use lower pressure coefficients compared to an open field (Exposure Category C). We don't ignore the wind; we calculate the correct 'Exposure Definition' to optimize the design lawfully."

2. The 135-Degree Hook (The Authority Test)

This is a small detail that tests if the engineer controls the site, or if the mason does.

The Lazy Practice: Masons love to bend tie hooks at 90 degrees because it is easier and faster. Unprofessional engineers let them do it to avoid conflict.

The Safe Practice: BNBC code mandates a 135-degree hook bent into the concrete core.

Why it Matters: During an earthquake, the concrete cover cracks and falls off. If the hook is 90 degrees, the ring opens up, the vertical rods buckle, and the column collapses. A 135-degree hook stays locked.

The Verdict: If the engineer says "90 degrees is fine," they are prioritizing the mason's comfort over the building's safety.

3. The "Soft Storey" Danger (Car Parking)

In Dhaka, almost every residential building has a ground floor reserved for car parking (open space) and brick walls on the upper floors.

The Risk: This creates a "Soft Storey." The top is stiff (walls), the bottom is flexible (columns). During an earthquake, the energy concentrates at the weakest point—the ground floor columns—causing them to snap.

The Trap: Cheap engineers use Excel sheets that cannot calculate "Stiffness Irregularity." They design the parking columns the same as the upper floors.

The Fix: A professional uses ETABS to analyze the stiffness ratio and will often increase the column size or add shear walls specifically at the parking level.

ACTION: The Interrogation Toolkit (5 Questions to Ask)

Now that the fraud is exposed, here are 5 questions a landowner must ask before hiring anyone. Do not just ask "How much?" Ask "How will you design?"

Question 1: "How many piles will my building need?"

The Trap: Asking for a guess.

The Dangerous Answer: "Sir, roughly 40-45 piles. 60 feet deep." (This is a guess based on thumb rules. It is dangerous.)

The Competent Answer: "I cannot tell you that yet. Please provide the Soil Test Report. I need time to calculate the capacity of the soil layers before I can give you a number."

Question 2: "How do you calculate wind load for a building inside a colony?"

The Dangerous Answer: "We don't need wind load inside a colony."

The Competent Answer: "We apply BNBC 2020 standards. Since it is inside a colony, we will calculate the Exposure Category (likely Type B) to determine the correct wind pressure. It will be less than an open field, but we must apply it to the frame analysis."

Question 3: "Do you enforce 135-degree hooks for the ties?"

The Dangerous Answer: "Masons complain about it, 90 degrees is standard practice."

The Competent Answer: "We strictly enforce 135-degree seismic hooks. It is mandatory for earthquake resistance. If the masons complain, we train them, but we do not compromise."

Question 4: "What software do you use for analysis?"

The Dangerous Answer: "I have my own Excel sheets," or "I have been doing this for 20 years, I don't need computer checks for small buildings."

The Competent Answer: "I use ETABS, TEKLA, or STAAD.Pro for structural analysis to check for torsion and drift, and SAFE for the foundation design. I can show you the 3D model if you visit the office."

Question 5: "What is your educational background?"

The Requirement: Ensure they are a B.Sc. in Civil Engineering from a recognized university. Structural design is physics, not drawing.

Conclusion: Ignorance is Expensive. Knowledge is an Investment.

Construction is one of the most expensive journeys of a person's life. It is not the place to trip over pennies only to lose millions.

A "reasonable" fee from a knowledgeable person—whether they are a famous veteran or a sharp young engineer—is an investment. A "cheap" fee from an ignorant person is a liability.

The Advice: Test the next engineer. Ask the hard questions.

Demand to see the math behind the design.

Demand to see the 3D model.

Demand code compliance.

Don't pay for a guess. Pay for a calculation.

Discussion

No comments yet. Be the first!